31 January, 2026

A Needle Control Valve is a precision flow-regulating component used in LPG systems to control gas flow accurately, maintain stable pressure, and enhance operational safety. Unlike on-off valves, needle valves allow fine adjustment of gas supply, making them essential for industrial and commercial LPG applications.

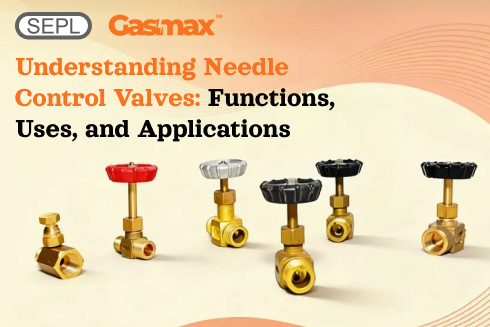

In India, SEPL, a trusted Needle Control Valve manufacturer and LPG gas accessories supplier in India, designs industrial-grade valves that ensure safe, steady, and controlled LPG flow across manifolds, pipelines, and burner systems.

A needle control valve is a flow controlling method designed with a tapered and narrow needle, such as those manufactured by an experienced LPG Needle Control Valve Manufacturer.

Allowing gas flow to be closely controlled at small openings.

Such precision is needed in the LPG applications since LPG is under pressure and extremely flammable. Elements such as an LPG needle control valve aid in the steady flow, avoidance of peaks of pressure, and enhancement of the overall system safe

The principle of working is straightforward yet very effective. When the valve handle is rotated, the needle gradually moves towards or away from the valve seat. The flow area is increased or decreased in tiny increments by this motion and allows fine regulation.

It is suitable in this mechanism because it makes it:

Balancing of pipeline pressure in LPG.

Minor gas dose adjustment.

Sudden change of flow is hazardous in applications.

At the big installations, the LPG pipeline needle valve is used to control distribution in various areas of the system.

The LPG systems work on different loads according to the consumption. The abrupt changes in pressure may destroy burners, regulators and safety devices. LPG gas has a needle valve that helps in a gradual and predictable flow of gas that directly causes stability of the system.

Key benefits include:

Less vulnerable to fluctuation of flames.

Better equipment lifespan

Minimized leaking or shocking of the pressure.

Improved safety compliance

The LPG needle control valve extensions are applicable in various industries where gas needs to be controlled precisely in various sectors.

Common Applications:

Furnaces and heating systems in industries.

Hotel gas lines and commercial kitchens.

Laboratory LPG setups

Gas distribution panels

Burner systems have an LPG needle-type burner valve that enables flame to be adjusted precisely, thus enhancing fuel economy and the quality of combustion.

Low-pressure LPG is not the only system. High-pressure supply lines are common in industrial installations. High-pressure LPG needle valve is specially designed to be made of strong materials, with strengthened sealing and pressure resistance.

These valves are applicable in:

Bulk LPG storage units

Industrial manifolds

Cylinder banks

Continuous-operation environments

In these types of environments, an industrial LPG needle control valve provides a high level of reliability in the rated environment.

A Needle Control Valve is normally fitted to LPG manifold assemblies used with components sourced from a reliable LPG VOT Manifold Accessories Supplier ensuring safe and consistent gas distribution across industrial systems.

The advantages of using these types of valves in industries are that the valves can be controlled in a way that is repeatable and consistent, which is essential in safety audits and operational efficiency.

SEPL has gained a reputation as a reliable supplier to industries that depend on LPG systems. Having decades of technical knowledge, the company manages to provide numerous industrial LPG accessories and safety elements that are developed to provide both accuracy, durability, and safety standards compliance.

Their solutions promote seamless processes, less downtime, and improved security in various LPG sites. Consult experts for safe LPG system guidance: Contact SEPL

A needle control valve should always be operated gradually to ensure safe LPG flow regulation. The valve handle must be turned slowly to increase or decrease gas flow in small increments. This controlled movement helps prevent sudden pressure surges, protects downstream equipment, and ensures stable burner performance. Regular inspection and correct installation further enhance operational safety.

In choosing a valve to be used in LPG applications, an individual should consider:

Operating pressure range

Compatibility with LPG Material.

Flow rate requirements

Type of application (burner, pipeline, manifold)

Safety standards and certification.

An effective choice guarantees the stability and sustainability of the system.

1. What is the primary reason for needing a needle control valve in LPG systems?

It is employed in the exact control of LPG circulation and stability of pressure under the conditions of safe operations.

2. Is it possible to use needle valves in the high-pressure LPG lines?

Yes, special high-pressure models can be applied in industrial uses of LPG.

3. Can needle valves be used in LPG burners?

Yes, they are popularly applied to regulate the intensity and amount of flame and gas in burners.

4. What is the difference between a needle and a ball valve?

Needle valves have control of fine flow, and ball valves are generally used for on-off applications.

5. In which locations are industrial LPG needle control valves expected to be found?

They are installed in manifold, pipeline, burner systems, laboratories and bulk LPG systems.

The flow of LPG is also a necessity, where it is necessary to have a high degree of precision, particularly in an industrial market and a commercial LPG system. Needle valves are important in safeguarding equipment and people by maintaining consistent pressure, regulated supply and greater safety. Selection of certified and well-developed LPG control components contributes to the efficiency of operation and reliability over the long-term perspective of every gas installation.

Need expert guidance for selecting the right LPG needle control valve or manifold accessories for your industrial setup? SEPL’s LPG system specialists can help you choose certified, application-specific solutions that ensure safety, accuracy, and long-term performance.

Contact our LPG experts: +91-9034576390 or Contact us

Also Visit - Optimizing LPG Usage: The Crucial Role of Needle Control Valves

Comments for